Dayco is a global leader in the research, design, manufacturing and distribution of essential engine products, drive systems and

services for automobiles, trucks, construction, agriculture and industry.

Dayco’s contributions are integral to how people get from place to place, goods are transported, food is harvested, and infrastructure

is built. The company operates according to long-held values — keeping promises, delivering on time all the time, and an intense

commitment to service no matter what the obstacles. For more than a century, Dayco has overcome challenges, emerging stronger and

smarter at every turn.

Dayco improves how the world moves by creating products, systems and relationships that endure.

Move Forward. Always.™

Timing Belts

Timing belts are designed both for applications in diesel and petrol engines, and are fitted both on motorcars and industrial vehicles.

With the use of new materials, the belts can be made in various structures and tooth profiles, to guarantee the performance of modern vehicles.

Nowadays, belts are subject to stresses and working conditions that seemed impossible only a few years ago:

- High fuel injection pressure, which can reach up to 2000 bar in some applications

- Multi-valve engines: double camshaft with higher stresses

- Engines with high power and operating temperatures over 120°C/250°F

They should also guarantee:

- Noise reduction

- Limited dimensional tolerances

- Limited variation of the belt dimensions in operation

- High resistance to cloth abrasion

- Longer service life/mileage

Available structures:

NR: first generation belts, generally not subjected to high workloads nor to high thermal stress (working temperature 80°C-90°C/175°F-195°C).

HSN: offers superior resistance to high working temperatures (even up to 110°C/230°F) and to pulsating loads.

HDT: are foreseen for some particularly heavy applications. To increase resistance to lateral wear, they are equipped with a special

fabric on the back, withstanding temperatures up to 115°C/240°F.

HT: with tooth tissue coated with a PTFE film (highly abrasion-resistant material), designed to minimize wear on tooth tissue.

They are mainly used on diesel engines of the latest generation and with high injection pressures: they guarantee maximum life span of the belt on the

engines, withstanding temperatures up to 120°C/250°F.

HK: latest generation product, equipped with aramid-based fibers for superior durability and noiselessness. They resist temperatures up to 120°C/250°F.

BIO: distribution belts designed to work in an oil bath. They resist the action of additives and the high temperatures of the engine oil.

Timing Belts HT

The latest engines, in particular diesel engines fitted with the last-generation Common-Rail system, are particularly critical. They subject the transmission

components to high mechanical stress due to high operating temperatures, high specific powers and very high injection pressures (over 2000 bar), often

combined with twin camshaft timing systems.

HT timing belts are Dayco’s solution: they guarantee the efficient and constant coupling between the various components of the transmission, even in case of

high mechanical stresses, making use of advanced materials and a special PTFE film that is coupled with the teeth covering fabric.

The HT belt can be easily identified with its unique white covering on the internal side, resulting from the presence of the PTFE film, an exclusive Dayco patent.

With this new technology, Dayco has succeeded in increasing the belt wear resistance during meshing with the pulleys (including the back side of the belt) and by

limiting the side wear caused by the contact between the belt side and the pulley flange.

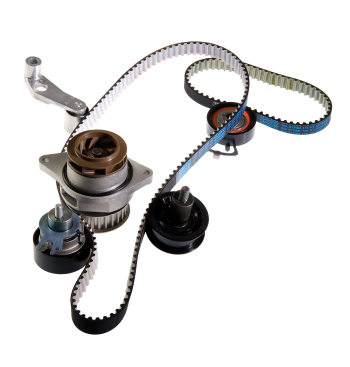

Timing Belt Kits with Water Pump

The engine cooling system is designed to stabilize the temperature, limiting its rise within the set limits. The cooling fluid is circulated by the water pump,

which must guarantee the correct flow at every engine rotation speed.

Failures in the system can cause significant damage to the engine. For this reason, it is extremely important that the water pump be systematically checked.

In many applications, the water pump is controlled by the timing belt. It is therefore highly important to check the water pump and replace it if necessary

during the timing control maintenance.

The main elements that guarantee the quality of our pumps are:

-

The bearing, which supports the rotor on one side and the pulley on the other side. This element must guarantee constant smoothness and react to the loads

generated by the control system. It is available with a double ring of balls or a ring of balls (rotor side) and a ring of rollers (pulley side).

The bearing geometry is determined by the vehicle manufacturer according to the loads generated by the system.

-

The rotor, which can be a synthetic material is reinforced with glass fiber, steel or cast iron. The profile of the tabs is very important as

they must guarantee the correct flow and prevent cavitation effects. The rotor manufacture is extremely complex as it must provide the fluid

constant flow at any engine rotation speed.

-

The seal, fitted between the rotor and the bearing. It must guarantee the liquid tightness at all operating temperatures and rotation speeds, in

order to prevent the liquid from entering the bearing, causing irreversible damage to the pump.

-

The pump body, usually in plastic or aluminium depending on the vehicle manufacturer. In both versions, the pump body must guarantee the system appropriate rigidity and geometry.

The water pumps in our kits are OE equivalent and provide maximum safety and service life.

Tensioners and Pulleys

The increasing performance of engines and the growing number of auxiliary units have required significant developments in the design and choice of materials for all rigid components.

The timing and auxiliary control components, both with fixed and automatic tensioning, must fulfil the manufacturers’ requirements, amongst which are:

- Increasingly reduced working spaces

- High injection pressures

- High temperatures

- High stresses

- Increased interval for component replacement

This implies that both the system tensioners (fixed and automatic) and pulleys must fulfil very high quality requirements.

The main types of rigid components are:

-

Fixed tensioners: the final tension on the belt is applied on assembly and remains constant over time. The belt tension is therefore determined when it is

assembled. In these cases, the use of the DTM Tensiometer is advised.

-

Automatic tensioner: spring-loaded or hydraulic. These are dynamic tensioners which, once installed, can adapt to and improve the belt tensioning according

to the engine stress, in any operating condition.

-

Guide pulleys: these pulleys, with or without bracket, allow the correct guiding of the belt in its route. They are very important as they support part of the system stresses.

Dayco supplies components of original quality or equivalent to the original for its own range, both for automotive and industrial vehicles.